AL-KO - Kötz, Germany

AL-KO is a giant not only in the leisure vehicle industry, but also in commercial trailers. In Kötz, they have capacity to produce over 2,500 axles a day and more recently, the company has diversify to other related products like air suspension, levelling systems for caravans and trailers or security devices like the AL-KO wheel locks you see in some Bailey ranges.

We met with Michael Nebel, Vice President of Caravan Sales , who gave us an inside of AL-KO headquarters in Germany.

SIMON: AL-KO is a real giant in our industry. Going back to the beginning, can you tell us how the company started?

MICHAEL: We are here in Bavaria in a small village called Kötz and very close to Ulm, which is very famous for having the highest church tower in the world, and is also the birth town of Albert Einstein. But this is just an story beside…

In 1931, in this small village, the founder of what later would be AL-KO started a forge business, making breaks for the local farmers’ trailers. That was the early beginning. From there, the company went bigger and bigger and last year we turned 90 years old.

SIMON: I believe you have recently changed ownership…

MICHAEL: That’s right. We were a family-owned company until 2016. We were acquired by the American company Dexter in the US. Dexter is the main company for supplying trailers in the US, and we are the biggest supplier for those products in the rest of world. So we were a very good fit. Merged together, we are now the biggest supplier in the trailer industry.

LEE: Virtually every caravan in the UK market now is on an AL-KO chassis. Understandably, you should be proud of that, but that must raise other challenges to grow your business. How do you go about selling other accessories? Or does that present a problem now that every caravan already comes with a well specified AL-KO chassis?

MICHAEL. Accessories are a very important business for us.

We have the core products, like the chassis, the axle, the coupling… Everything you need to build a caravan in your factory. But on top of that, we have a lot of accessories which gives your customers more comfort, more security…

In the UK we have the specific situation that caravans come very highly equipped with additional accessories as standard. For example, about 70% of caravans in the UK come with ATC, which gives you more security when driving. Also security devices, like the AL-KO wheel locks to protect your caravan from being stolen are widely fitted as standard.

In general, caravans in the UK come very well fitted from the beginning, so we have to look for new accessories to make caravanning easier.

For example, recently we have bought a company called E&P that makes levelling systems. With the push of a button, this allows the customer to level the caravan when on site.

"Caravans in the UK come very well specified as standard, so we have to look at new accessories that add value"

SIMON: It’s all about adding value to the ownership and enhancing enjoyment of the caravan and additional peace of mind with safety and security.

We know you supply chassis for caravans and motorhomes, but that’s not all you do. You’re involved in several other markets…

MICHAEL: The leisure vehicle market is key for us. We make caravan and motorhome chassis and all the accessories we mentioned earlier. But the biggest market is in commercial trailers, like horse trailers, stock trailers, … Anything you can imagine that can be pulled by a car.

We also get involved in other businesses by the acquisition of other companies. For example, last year we bought a company called Blink that make hitches for cars to tow a caravan, for example.

We have diversified a bit in the past years but most of our businesses are close to our core one: trailers.

SIMON: We are in Kötz today. Can you tell us what part of your operations goes on here?

MICHAEL: We are in AL-KO headquarters. Our board sits here, our management, and we have some central functions here. Most logistics run from here too. All the materials coming from suppliers or from our factories in Europe come here and then go out to our subsidiaries or our customers.

We also home all the Research and Development here. We have the testing department here in Kötz, which is very big and knowledgeable.

We produce all the chassis parts and all our axles. So this is the main factory for our main products, and then we have different production sites all over Europe. In Italy we make the overrun devices and the coupling for the caravans. In Austria we make the drums and the normal couplings. And in France, for example, we make axles for motorhomes.

All over Europe we have sites that specialise in certain parts and then it all come to us here in Kötz.

SIMON: So effectively you are assembling everything here, including the chassis and the axle we are sitting on now?

MICHAEL: We produce both things here, load it in lorries and then it all comes to your site in Bristol, where you mount it all together in your factory.

"Our headquarter is here in Kötz but we have factories all over Europe"

LEE: Talking about mounting at the factory, how do you ensure that your quality control follows on at Bailey? Is there a vendor vetting process to ensure that everything is assembled correctly?

MICHAEL. Yes. This is important because our claim is quality for life. And it’s not only at product development and production but we also assure that our customers do things right. We offer our customers audits and training at least once a year. Our quality management team reach out to our customers and do assembling tours, show them what’s new, etc.

We offer this to every customer in Europe and most take the offer because they are also interesting in knowing they are doing things right.

SIMON: We at Bailey have very close involvement with AL-KO UK in Southam in Warwickshire. They come to the factory regularly and get involved in the design process of new products, coming with recommendations for the chassis.

What else do they at Southam? What tasks do they perform at AL-KO UK?

MICHAEL: I think Southam was founded in 1969, so we have a long history also in the UK. It was one of our first factories abroad.

In the UK they make axles for your market. They get the chassis from us in Kötz and accessories and they make the axles. They also produce wheel carriers.

But their main activity is to do with sales and to act as the customer contact in the UK to sell our big range of products.

Also in the UK, we bought a company in 2019 that is the main producer of chassis for static homes. The UK is the biggest market in Europe for static homes and I believe they make 90% of their chassis. They are in East Yorkshire, and they do a fantastic job there.

LEE: Looking to the future, is there anything AL-KO is looking at developing or changing with your product? Anything you can tell us?

MICHAEL: Perhaps we can’t tell you everything but of course as a company we think about the future and see the changes coming our way for example with E-mobility. We talk with our customers, with universities, with partners, … to find the right solutions for the future.

One thing we are looking at already is lightweight. With the Vario X chassis we established two or three years ago we managed to save 30% of the weight of the chassis by using bionic thinking. We did a lot of calculations, we looked at where the strength is in the chassis are and looked at areas where we could save in height or thickness.

This is a great example of how we can work on things with an eye to the future.

SIMON: AL-KO as a business is tremendously successful, but like all other businesses in Europe, we’ve faced two major challenges recently. Starting with Brexit, how has that affected you here in Germany?

MICHAEL: At the beginning we had some issues with documentation and legal, and some issues with delivery times. But our organisation is very flexible and could handle it.

SIMON: I understand that not only you ship products to the UK, but you also buy components from the UK. Not necessarily for caravans, but for other vehicles.

MICHAEL: Yes, we do. For example, we have a company making overrun devices for commercial trailers. For caravans, spare wheel carries come for the UK.

"Steel is our main raw material and it has doubled in price in the past year"

SIMON: It seems like you’ve managed Brexit successfully. While with Brexit we had a bit of notice, with COVID, we certainly didn’t. That was sprung on us globally. How did you cope with that?

MICHAEL: In general of course we had problems. We had big supply problems. We had suppliers that went into shutdown. We had our own problems here with workers as well. From one day to another you could have 50 people affected. So we had to handle a lot of things. We have a lot of taskforces. But at the end of the day, people came closer together.

We have now established task courses with different functions. They still meet today every week. So, if you look at the positives during COVID is that teams came closer and work very close together still today.

It was hard. It’s still hard to get the right material in the right time. Right now we have problems with electronic components, much like the car industry.

LEE: You touch upon supply. Do you have the same problems as every other supplier we’ve visited with regards to getting raw materials and the cost of them?

MICHAEL: We’ve had different situations. Last year, and I’ve never seen this before, we had serious problems to get steel. We could have never imagined that we wouldn’t be able to get steel. We buy big coils of it and you cannot start production without because 90% of the raw material in our products is steel.

From a cost perspective, steel has doubled in price in one year, something we have never seen before. You can imagine what the consequences are for us to manage those costs. And, of course, we had to bring the cost up for our customers as you cannot absorb all the price increase.

SIMON: As a business how are you looking to reduce your carbon footprint going forward?

MICHAEL: At a production level, when we invest in new machinery, we look at efficiency, power requirements, etc.

This is from an investment and production point of view, but we also look at our products. Using steel to make a new chassis is cost effective, and you can recycle steel very easily.

If we used other materials like magnesium, it would be a lot harder to recycle.

SIMON : I’m also guessing that, if you’re taking 30% out of the weight of the chassis with the new product you mentioned earlier, that must also have huge environmental implications by reducing the vehicle emissions when they’re being towed.

Yes, that’s right. And the other thing is that, if you need 30% less of steel, you need less of the raw material in the first place.

SIMON: Yes, less material, more efficiency. It’s a win-win.

END

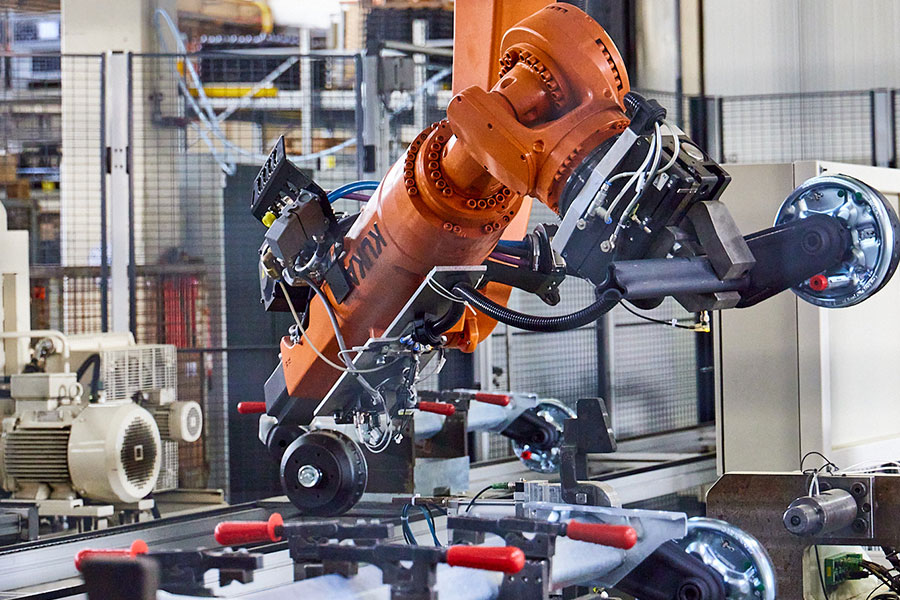

Images from our day at AL-KO

Take a look at the gallery below to see images from our day at AL-KO. Hover over the information icon on each photo to read the caption.